OIL & GAS

Bundle Pulling

Elevate Your Oil and Gas Operations with Premier Bundling Pull Services!

Maximize Your Oil and Gas Efficiency with Expert Bundling Pull Services!

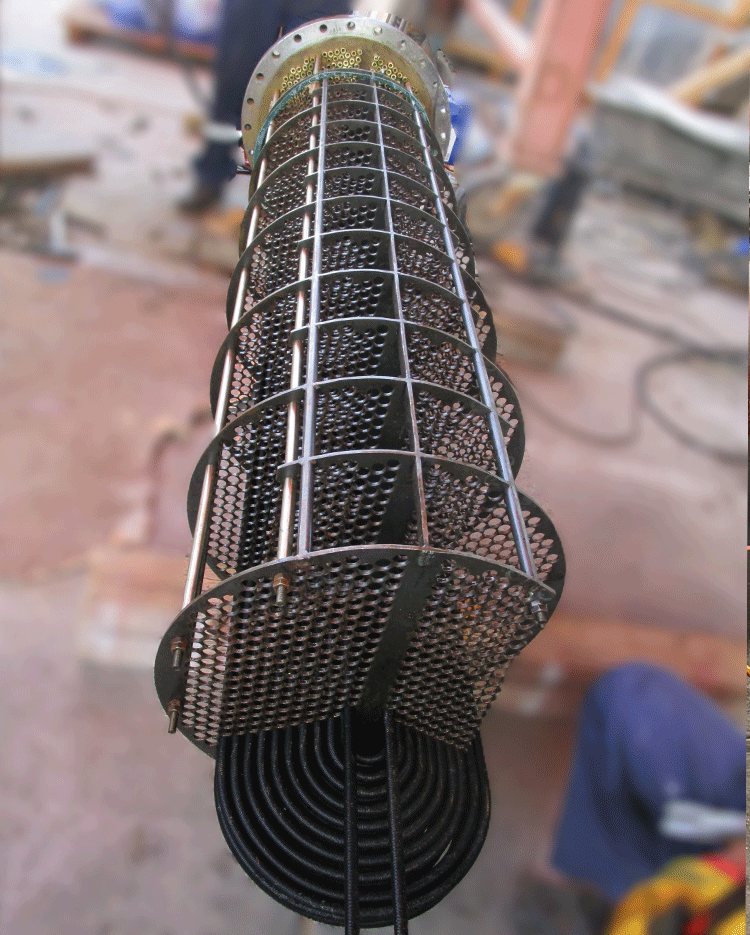

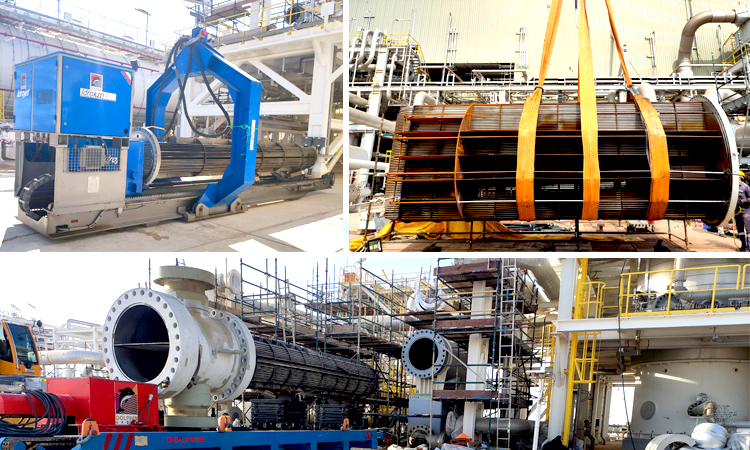

In the fast-paced oil and gas industry, reliable Bundling Pull services are essential to boost operational efficiency and ensure safety. Our specialized service focuses on the extraction of tube bundles from heat exchangers for thorough inspections, cleaning, and repairs, effectively addressing fouling, scaling, and debris buildup.

Regular bundle pulling prevents costly downtime and inefficiencies, safeguarding your equipment’s structural integrity. Our expert team ensures proactive problem detection, allowing your systems to run at peak performance. Enjoy enhanced heat transfer efficiency, prolonged equipment lifespan, and minimized operational disruptions with our routine maintenance services.

Investing in bundle pulling is a strategic choice for uninterrupted production and regulatory compliance. Let us help you maintain a safe and economically viable operation.

FEATURED

Why Choose Us?

We deliver high-quality, durable, and customizable solutions for radiators, coolers, and HVAC systems across various industries. With expertise, innovative designs, and a commitment to excellence, we ensure optimal performance, reliability, and efficiency for all your cooling needs.

Dedicated Team

True Partners

Global Know-How

Focus On Innovation

RELATED PROJECT

Projects in the field

Heat Exchangers

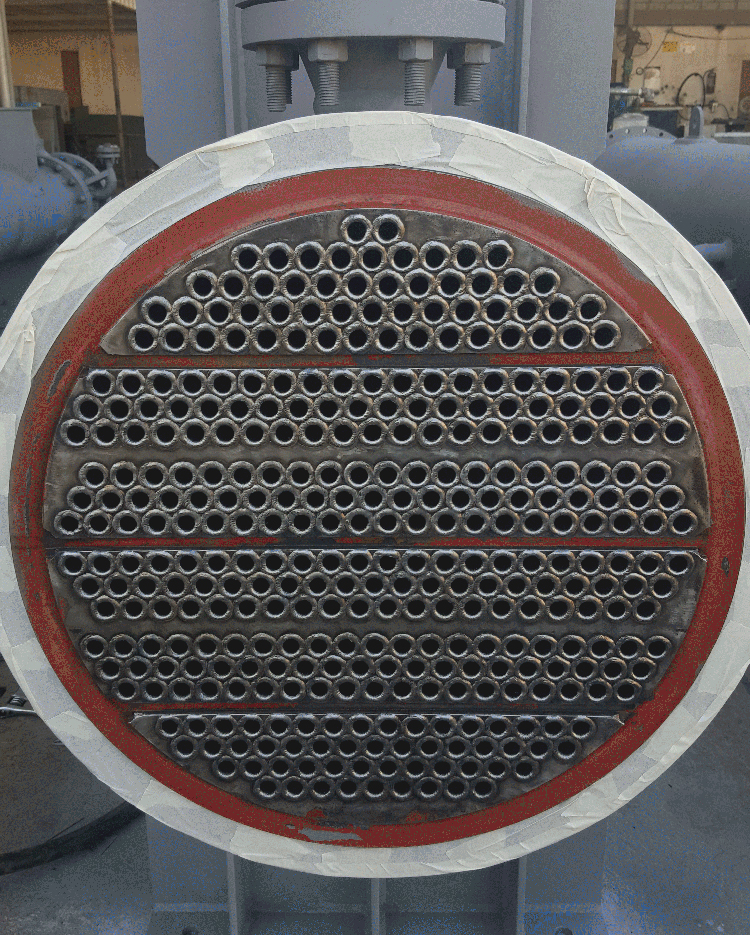

We successfully refurbished 16 seal oil coolers, which included replacing tubes and overhauling 3-way valves. Each cooler was tested at a pressure of 90 bar, and we applied a specialized anti-corrosive coating on the tube sheet to enhance durability and performance.

Retubing

We executed a heat exchanger tube bundle replacement project for the Main Column Trim Condenser during a refinery shutdown. This involves replacing 12 bundles, each with 1,060 CuNi 70/10 tubes, with a completion timeline of 4 weeks. Our goal is to boost efficiency and reliability while minimizing downtime.